Choosing the right stainless steel pipe fittings can help prevent issues such as leaks. Each type has its own strength. NPT works well in high-pressure systems, and BSP is good for plumbing and medium pressure. Flanged fittings, on the other hand, are best for large or corrosive systems. The right choice depends on several factors, including pressure, pipe compatibility, and intended use.

In this guide, you will learn:

- The key features of NPT, BSP, and flanged connections

- How to tell them apart and when to use each

- Whether BSP and NPT threads are compatible

- Which fittings suit various industries

Let’s dive in and clear up the confusion around NPT vs BSP vs Flanged pipe fittings.

Overview of Pipe Threading Standards

Pipe threads are the spiral ridges on pipe ends or fittings that allow them to connect tightly.

Why do pipe thread types matter?

- They ensure leak-proof connections for liquids and gases.

- Different industries have their own regional standards and preferred thread types.

- Using the wrong thread can cause leaks, damage, or safety hazards.

Regional Standards

- NPT: Mainly used in the U.S.

- BSP: Common in Europe, Asia, the UK, and Australia

- Flanged connections: Used globally, especially for heavy systems

Questions like “Are BSP and NPT threads compatible?” come up often. The short answer is no. Their thread angles and pitches differ, making them incompatible without adapters. Threads are vital in pipe fitting stainless steel systems: you can’t mix them up.

Understanding these differences prevents costly mistakes. A simple thread mismatch can turn a 10-minute job into hours of work and hundreds of dollars in new parts.

NPT (National Pipe Thread): Features & Use Cases

NPT threads are the most common pipe threading system in North America. Here’s what makes them special:

Key Features of NPT Threads

Tapered Design:

- NPT threads get tighter as you screw them in

- Uses a 60-degree thread angle

- Creates a pressure-tight sealwithout extra sealing materials

High Pressure Rating:

- Can handle up to 3,000 psi in many applications

- Perfect for high-pressure systems like hydraulics and compressed air

Common NPT Sizes and Specifications

Popular NPT sizes include:

- 1/4 NPT – Small instruments and gauges

- 3/8 NPT – Medium pressure lines

- 1/2 NPT – Standard plumbing applications

- 3/4 NPT – Larger flow requirements

Technical Example: A 1/2-inch NPT fitting has a thread pitch of 1.814 mm, meaning there are about 14 threads per inch.

Where NPT Fittings Work Best

NPT fittings excel in:

High-Pressure Piping Systems:

- Hydraulic systems

- Compressed air lines

- Steam applications

- Oil and gaspipelines

Industrial Applications:

- Chemical processing (with proper materials)

- Power generation

- Manufacturing equipment

- HVAC systems

The tapered design of NPT threads makes them self-sealing, which is why they’re preferred for high-pressure applications where leaks could be dangerous or costly.

Save costs by choosing NPT fittings in applications requiring strong seals and pressure resistance. They reduce leak risks and maintain system integrity.

BSP (British Standard Pipe): BSPP vs BSPT

BSP threads are pipe connections used around the world, especially in Europe and Asia. They come in two different types that work in various ways.

BSPP (British Standard Pipe Parallel)

BSPP threads stay the same width down the pipe. Think of them like a straight tube – they don’t get tighter as you screw them in.

How BSPP Works:

- Needs rubber O-rings to stop leaks

- Easy to take apart for cleaning

- Good for food processing because they’re smooth inside

- Used for low pressure – up to 150 psi

Where You’ll See BSPP:

- Food and drink factories

- Water pipes in buildings

- Easy-to-clean systems

BSPT (British Standard Pipe Taper)

BSPT threads get tighter as you screw them in, just like NPT threads. The pipe gets narrower toward the end.

How BSPT Works:

- Seals itself – no O-rings needed

- Handles more pressure than BSPP

- Gets tight when you screw it in

- Used for medium pressure – up to 2,500 psi

Where You’ll See BSPT:

- Factory equipment

- Medium-pressure water lines

- Equipment from Europe and Asia

Key Differences Between BSPP and BSPT

| Feature | BSPP | BSPT |

| Thread Shape | Parallel | Tapered |

| シーリング | Needs O-rings | Seals itself |

| Pressure | Low (150 psi) | Medium (2500 psi) |

| Best For | Food/easy cleaning | General industry |

Both BSP types use 55-degree thread angles, which is different from NPT’s 60-degree angle. This means BSP and NPT don’t work together without special adapters.

NPT vs BSP vs BSPT vs BSPP: Key Differences

Understanding these differences prevents costly mistakes and ensures proper sealing. Here’s a detailed comparison:

| Feature | NPT | BSPT | BSPP |

| Thread Angle | 60° | 55° | 55° |

| Thread Profile | Tapered | Tapered | Parallel |

| Seal Type | Thread seal | Thread seal | Requires an O‑ring or a gasket |

| Pressure Rating | High (up to 3,000 psi) | Moderate (up to 2500 psi) | Lower (depends on the sealing ring) |

| Geographic Use | US, North America | UK, EU, Asia | UK, EU, food & sanitary systems |

Visual Guide:

How to spot the differences:

NPT Threads:

- Sharper, more pointed peaks

- Gets noticeably tighter when screwing in

- Thread peaks look more triangular

BSP Threads:

- Slightly flatter thread peaks

- BSPP stays the same tightness throughout

- BSPT gets tighter like NPT, but with a different angle

Pressure and Performance Differences

NPT Advantages:

- Higher pressure ratings

- Self-sealing design

- Widely available in North America

- Strong mechanical connection

BSP Advantages:

- Better for food-grade applications (BSPP with O-rings)

- Easier to disassemble and clean

- Less likely to gall (stick together)

- More forgiving installation

Real-World Example: A 3/4 NPT and a 3/4 BSPT fitting might look the same, but their threads are shaped differently. If you mix them, they won’t fit right and could leak. This kind of mistake can cost hundreds of dollars to fix and stop work for hours.

Are BSP and NPT Threads Compatible?

No, they are not compatible without adapters.

Here’s why this matters and what happens when people try to mix them.

Why BSP and NPT Don’t Mix

Thread Angle Differences:

- NPT uses 60-degree angles

- BSP uses 55-degree angles

- These don’t line up properly when screwed together

Pitch Differences:

- Different spacing between threads

- Creates gaps that prevent proper sealing

- Leads to cross-threading and damage

What Happens When You Force-Fit Different Threads

Common Problems:

- Immediate leaks ( even with thread sealant)

- Thread damage (expensive parts get ruined)

- Safety hazards (unexpected failures under pressure)

- Costly repairs (entire sections may need replacement)

Solutions for Mixed Threading Systems

BSP-to-NPT Adapters:

- Special fittings with different threads on each end

- Available in most common sizes

- Add cost but prevent problems

Dual-Threaded Fittings:

- Some manufacturers make hybrid fittings

- More expensive but very reliable

- Good for permanent installations

Always check your existing system before ordering new fittings. Can BSP be used with NPT? Only with proper adapters – never force incompatible threads together.

Flanged Connections vs Threaded Connections

Flanged connections work differently from threaded ones. Instead of screwing pipes together, flanges use bolts to join two flat, round pieces with a rubber seal in between.

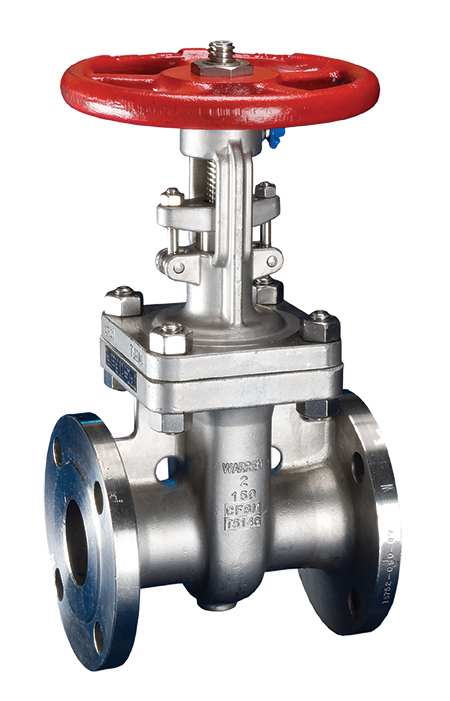

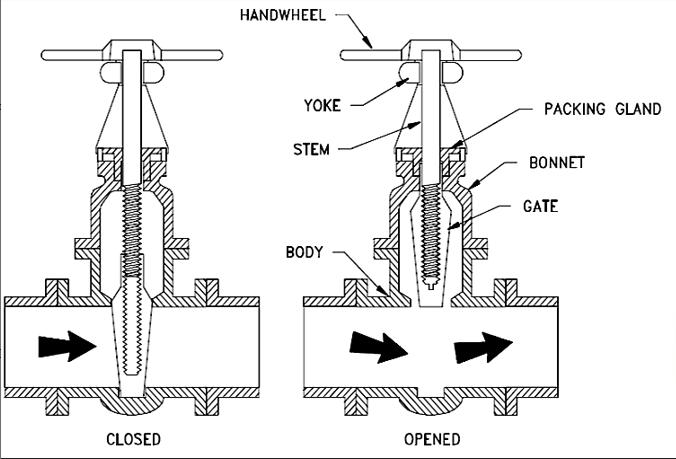

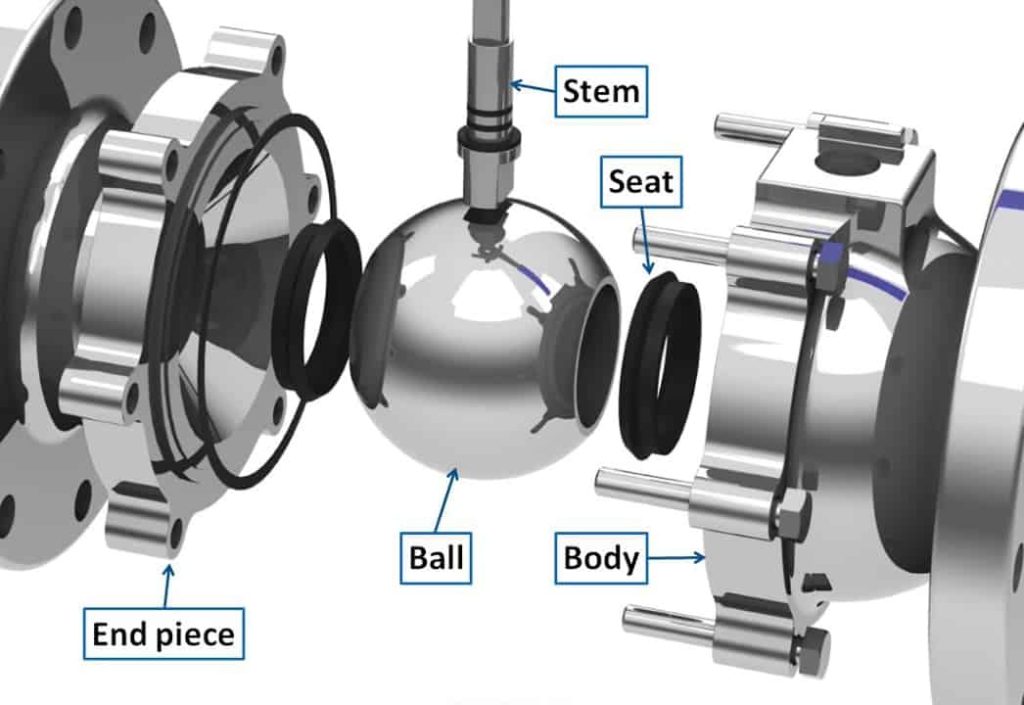

What Are Flanged Connections?

Flanged connections join two materials with flat surfaces that bolt together. Think of them like two dinner plates with holes around the edges that you bolt together with a rubber gasket between them.

How They Work:

- Flat, round discs welded to pipe ends

- Bolt together with gaskets for sealing

- Much stronger than threaded connections

- Easy to take apart when you need to fix something

Types of Flanges

Slip-On Flanges:

- Slide over the pipe and weld in place

- The cheapest option to buy

- Good for systems that don’t have high pressure

Weld Neck Flanges:

- Weld directly to the pipe wall

- Strongest connection you can get

- Best for high-pressure and high-temperature jobs

Blind Flanges:

- Close off pipe ends completely

- Used for testing systems or future connections

- Easy to remove when you need to add more pipes

Threaded Flanges:

- Screw onto NPT or BSP threads

- No welding needed

- Good when you might need to move them later

When to Choose Flanged Over Threaded

Flanged connections can handle higher pressures and temperatures better than threaded connections.

Pick Flanged When You Have:

- High pressure (up to 6,000 psi) in 316 stainless steel

- High temperature (up to 800°C)

- Big pipes (over 2 inches wide)

- Dangerous chemicals that could hurt people if they leak

- Systems you fix often, flanges are easier to take apart

Flange Connection vs Threaded: Simple Comparison

| Threaded | Flanged | |

| Cost to Buy | Cheaper | More Expensive |

| Time to Install | Faster | Takes Longer |

| Easy to Fix | Hard to take part | Easy to unbolt |

| How Strong | Good for regular jobs | Very strong |

| Space Needed | Small | Takes more room |

Bottom line: Flanged connections cost more initially but work better for demanding jobs and last longer when you need high pressure or easy maintenance.

Speciality Thread Types & Global Variants

Beyond NPT and BSP, several other threading standards exist worldwide. Understanding these helps when working with international equipment or suppliers.

G Fittings vs NPT

G Threads (ISO 228):

- Same as BSPP (parallel BSP)

- Used throughout Europe and Asia

- Requires O-ring sealing

- G vs NPT: Not compatible without adapters

Common Applications:

- European hydraulic systems

- Asian manufacturing equipment

- International pneumatic tools

PF vs NPT (Japanese Metric)

PF Threads:

- Japanese metric pipe thread

- Similar taper to NPT but metric sizing

- Common in Japanese and Korean equipment

- PF vs NPT thread: Different pitch and sizing

Where You’ll Find PF:

- Japanese machinery imports

- Korean industrial equipment

- Some metric hydraulic systems

UNF vs NPT (Unified National Fine)

UNF Threads:

- Machine threads (not pipe threads)

- Much finer pitch than NPT

- Used for mechanical connections (not plumbing)

- UNF vs NPT fitting: Completely different applications

JIS vs NPT (Japanese Industrial Standard)

JIS Threads:

- Japanese Industrial Standard

- Used in Japanese industrial equipment

- Similar to BSP but with metric sizing

- JIS vs NPT: Requires adapters for compatibility

Regional Usage Examples

Asia-Pacific:

- Japan: JIS and PF threads

- China: Mix of BSP and metric threads

- Australia: BSP standard

Europe:

- Germany: BSP and metric threads

- UK: BSP throughout

- France: Mix of BSP and European standards

Americas:

- USA/Canada: NPT standard

- South America: Mix of NPT and BSP

- Mexico: Primarily NPT

Always check equipment documentation for thread specifications when working with international machinery.

How to Identify and Measure Threads

Finding the right thread type stops leaks and saves money. Here are simple ways and a detailed video to help you know what you have.

Tools You Need

- Thread pitch gauge: This tool helps you count how many threads there are in a certain length.

- Calipers: These measure the size of the pipe’s outside or inside diameter.

How to Determine Pipe Thread Type and Pipe Size in 5 Steps

Quick Ways to Tell Threads Apart

Look at the Shape:

NPT Threads:

- Get tighter as you screw them in

- Have sharp, pointed tops

- Usually say “NPT” on the part

- Common on American-made equipment

BSP Threads:

- BSPP: Stay the same width all the way

- BSPT: Get tighter like NPT but with a different angle

- Often marked “BSP” on the fitting

- Common on equipment from Europe or Asia

What does BSP stand for in fittings? BSP means “British Standard Pipe” – a threading system used in many countries outside North America.

Simple Steps to Measure

For Threaded Parts:

- Clean all dirt off the threads

- Measure the width with calipers

- Count how many threads per inch

- Check if it gets tighter when screwing in

- Look for any letters or numbers stamped on it

How to tell the difference between NPT and BSPT

- NPT threads are sharper and more pointed

- BSPT threads are slightly flatter on the outside

- Use a thread gauge to be sure

- NPT uses 60-degree angles, BSPT uses 55-degree angles

Always check with your supplier or look at product sheets to be sure you have the right fitting. This helps stop mistakes that cause leaks or damage.

Choosing the Right Stainless Steel Pipe Fittings by Industry

Different types of work need different pipe connections. Here’s how to pick the best one for your job.

Food & Beverage Companies

Best Choices:

- BSPP with rubber rings for easy cleaning

- 3-A certified fittings that meet food safety rules

- Smooth inside surfaces so food doesn’t stick

Why These Work:

- Easy to wash – no hidden spots for germs

- Food-safe materials– won’t make people sick

- Quick to take apart for deep cleaning

- Smooth flow – no bumps to catch food bits

Real Example: Dairy plants use 316L stainless steel BSPP fittings with special rubber rings. This keeps milk clean and makes washing between batches fast and easy.

Chemical Plants

Best Choices:

- Flanged connections for high pressure and dangerous chemicals

- NPT threads for smaller pipes with high pressure

- Special metal alloys that don’t get eaten by chemicals

Why Flanges Work Better:

- Handle very high pressure – up to 6,000 psi or more

- Easy to fix when something goes wrong

- Strong and safe for dangerous chemicals

- Required by law in many chemical plants

HVAC & Water Systems

Most Common:

- NPT threads because they’re easy to find and work well

- Flanged connections for big pipes

- BSP threads when working with equipment from other countries

Why NPT is Popular:

- Available everywhere – any hardware store has them

- Handles normal pressure well (up to 3,000 psi)

- Costs less than other types

- Easy to install with standard tools

結論

Picking the right stainless steel pipe fittings keeps your systems safe and saves you money. Here’s what you need to remember:

The Three Main Types

NPT Threads:

- Best for: High pressure in North America (up to 3,000 psi)

- Good points: Seals itself, very strong

- Watch out: Won’t work with BSP threads

BSP Threads:

- Best for: Easy-to-clean systems, international equipment

- Good points: Easy to take apart and wash

- Watch out: Not as strong as NPT

Flanged Connections:

- Best for: Very high pressure, big pipes, dangerous chemicals

- Good points: Strongest option (6,000+ psi), easy to fix

- Watch out: It costs more at first

Key Takeaways

- BSP and NPT don’t work together – you need special adapters

- Always check what threads you have before buying new parts

- Match your fittings to your pressure and temperature needs

- Follow safety rules for your type of work

Quick Picking Guide

- High pressure? Use NPT or flanged

- Need to clean often? Use BSPP with O-rings

- Working with chemicals?Use flanged connections

- Standard plumbing?NPT is usually best

- International equipment?Check for BSP threads.

Remember: Spending a little more on the right fittings now prevents big problems and expensive fixes later.

Need Expert Help?

Don’t guess with pipe fittings. Mistakes cost thousands in repairs and downtime. Contact ProCamlock today for free advice on choosing the right connections for your system. Procamlock is a leading supplier of stainless steel pipe fittings, specializing in NPT, BSP, and flanged connections. We ensure:

- Certified 3‑A sanitaryand ASME B16.5 flanges

- Expert support for thread compatibility and custom adapters

- High‑pressure rated fittings up to 6,000 psiat temperatures up to 800 °C

- Global shipping with stock in the US, EU, and Asia

Choose us for reliable, safe, and compliant pipe fitting solutions.

Contact Procamlock for a quote or technical consultation.

よくある質問

- How can you tell if NPT and BSP threads work together?

They usually don’t work well together. NPT threads get smaller as they go in, but BSP threads stay the same size. It’s like trying to put a cork into a straight tube – it won’t seal properly.

- Can BSPP fittings handle high pressure?

Yes, but you need good rubber rings (O-rings) and the right materials. The parallel threads with O-rings can handle high pressure very well when done correctly.

- Are NPT fittings better than BSP for chemical plants?

It depends on your specific needs. NPT offers higher pressure ratings (up to 3,000 psi) and self-sealing properties. BSP with O-rings provides better chemical resistance and easier maintenance. For critical chemical applications, flanged connections are often the best choice due to their superior pressure ratings and maintainability.

- How do you connect BSPT threads to NPT pipe?

Use a BSPT-to-NPT adapter fitting. These special fittings have BSPT threads on one end and NPT threads on the other. Never try to force BSPT and NPT threads together directly – the different angles will cause leaks and damage.

- What does a flanged stainless steel pipe connection look like?

A flanged connection consists of two flat, round metal discs (flanges) welded or threaded to pipe ends. The flanges have bolt holes around the perimeter and bolt together with a gasket in between. This creates a very strong, leak-proof connection that’s easy to disassemble for maintenance.

- Can you use BSP threads for food-grade connections?

Yes, if you use food-safe materials like special stainless steel and food-grade O-rings. The threads themselves are fine – it’s the materials that matter for food safety.

- How do you measure NPT vs BSP threads correctly?

Use a thread pitch gauge for accurate identification. NPT threads have a 60° angle and specific pitches (like 14 TPI for 1/2”). BSP threads have a 55° angle and different pitches. Also check if threads are tapered (NPT/BSPT) or parallel (BSPP). When in doubt, consult the manufacturer’s specifications.

- Is 1/2-inch BSP the same as 1/2-inch NPT?

No, they are completely different, even though they’re both called “1/2-inch.” The thread angles, pitches, and actual measurements are different. A 1/2-inch BSP fitting will not properly seal with a 1/2-inch NPT pipe. You need an adapter or matching thread types.

- What fittings should you use for 316 stainless steel pipe in oil and gas?

For oil and gas applications, use high-pressure flanged connections for main lines and NPT threads for smaller instrument lines. The fittings must be NACE compliant for sour service and API certified. Use duplex or super duplex stainless steel for extreme conditions and corrosive environments.

- When should you use flanged connections instead of NPT or BSP?

For large pipes, high-pressure systems, or when frequent disassembly is needed.